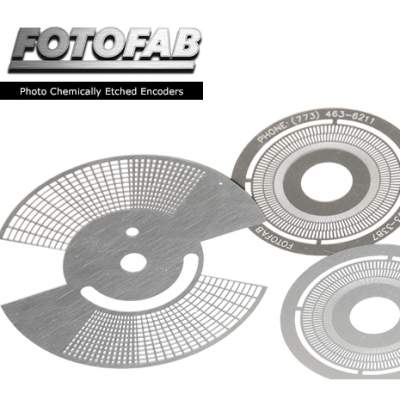

Fotofab’s photochemical etching process is well suited to making a large number of very small holes in sheet metal simultaneously. It costs the same to produce one hole as it does to fill an entire sheet of metal with holes. We are able to produce rotary and shaft encoders with finer features and holding tighter tolerances than other manufacturing methods.

Max sheet size is 24”x36” with the default sheet being 12”x18” and varying thicknesses available. Part tolerance varies with the metal thickness; generally, the thicker the metal, the wider the feature tolerance. Fotofab stocks a wide selection of metals with various tempers and thicknesses so we can meet your requirements fast. Parts can be made from never before seen drawings to fully realized parts in only 3 business days. Some stock parts are available for next day or same day shipping.