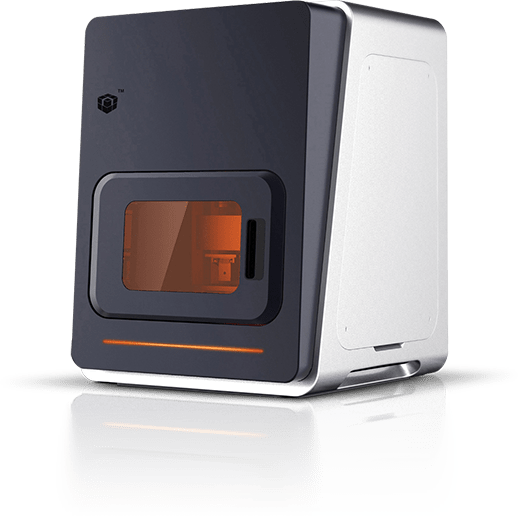

The 10µm series is the ideal solution for businesses and universities required ultra-high resolution, accuracy and precision in a desktop package. Within the 10µm series, the S240 is our industrial workhorse, with the ability to print with engineering-grade materials and a larger build volume – specifically designed to meed the needs of industrial production. BMF’s 10µm 3D printers offer a level of precision and accuracy that delivers the most challenging micro parts at production quality. The 2µm series includes three printers: the mircoArch P140, microArch S140, and microArch S240.

All of the printers in our 10µm series use a UV-LED (405nm) light source with an optical resolution of 10µm. The printers can print layer thicknesses of 10µm – 40µm. Parts printed on a a 10µm series printer will have a top surface finish of 0.4-0.8µm Ra and side surface finish of 1.5-2.5µm Ra. The printers use photosensitive resin as the printing material.

The microArch P140 has a build area of 19.2 x 10.8 x 45mm. The microArch S140 has a build area of 94 x 52 x 45mm. The microArch S240 has a build area of 100 x 100 x 75mm.

Features

The printers in our 2µm series feature a customizable, high-resolution optical system and movement platform with resolution down to 10µm. The step-and repeate process allows for the achievement of both high resolution and large area. The controlled processing technology produces highly precise 3D printed objects. The system allows for real-time monitoring, auto focus, and exposure compensation. The operating software offers a graphic interface system and customer parameter settings.