- VESTAKEEP® Care M40 3DF for medical applications with body contact up to 30 days

- New possibilities in the individual treatment of patients

- Further filaments for additive manufacturing in the pipeline

Shanghai/Darmstadt. Evonik has developed a new 3D-printable PEEK biomaterial for medical technology. With VESTAKEEP® Care M40 3DF, the specialty chemicals company is launching a polyether ether ketone filament for medical applications with body contact up to 30 days. The high-performance polymer can be processed in common extrusion-based 3D printing technologies such as fused filament fabrication (FFF) or fused deposition modeling (FDM). With the product launch, Evonik is expanding the possibilities for individual treatment of patients using additive manufacturing.

Biomaterials for individual patient treatment

The new PEEK filament is the latest addition to Evonik’s “Care Grade” line based on the high-performance polymer VESTAKEEP® Care M40. The product impresses with its biocompatibility, excellent temperature and chemical resistance, very good sterilizability, and easy handling. The range of possible applications extends from patient-specific hearing aids to filigree prostheses and orthoses to surgical drilling aids for dentistry or individual surgical instruments.

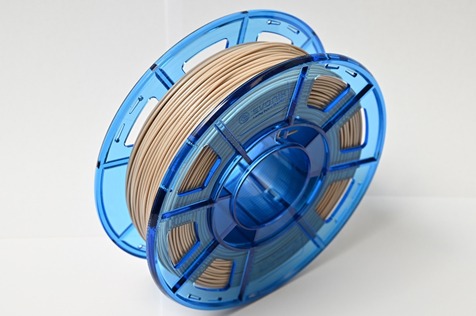

With a diameter of 1.75 mm, VESTAKEEP® Care M40 3DF is supplied in natural color on 500-gram spools that can be used directly in standard FFF/FDM 3D printers for PEEK materials. The filament is manufactured under cleanroom conditions and then subjected to strict quality management for medical materials.

Revolutionizing medical technology

“Following the commercial success of our VESTAKEEP® i4 3DF filament for 3D printing long-term permanent implants, we are now expanding the possibilities of modern medical technology for the individual treatment of patients with this new Care product,” says Marc Knebel, head of the Medical Devices & Systems market segment at Evonik. “In order to open up further medical applications for even better quality of life, a broad material landscape is needed. We have our fingers on the pulse with our portfolio of 3D biomaterials and are consistently developing it further. Doing so, this year we plan to launch an innovative PEEK-based filament with osteoconductive properties allowing bone cells to adhere to implants more quickly. Our goal is to revolutionize medical technology by offering innovative material solutions.”

For more than 20 years, Evonik has been the world’s leading manufacturer of high-performance polymers and additives used in additive manufacturing. The specialty chemicals company offers the industry’s most extensive portfolio of GMP-grade biomaterials used in the 3D printing of medical device parts designed for temporary and permanent body contact. In addition to VESTAKEEP® i4 3DF and VESTAKEEP® Care M40 3DF, the portfolio includes the RESOMER® line of bioresorbable filaments, powders and granules for implantable medical devices.

VESTAKEEP® Care M40 3DF – Evonik presents a new 3D printable PEEK Care Filament with body contact up to 30 days for more individualization in medical technology.