Medical device engineers know the importance of providing a product that meets that needs of the professionals using it and the patients who benefit. Many designs depend on accurate, repeatable control of pneumatic pressure and flow, whether part of the manufacturing process or on the product itself.

Proportion-Air is a leader in electro-pneumatic pressure regulators and flow control devices. We design and custom build our products to our customers’ exact specifications for pressure range, electronic inputs and outputs, units of measure and more.

Trusted around the world and across many industries, Proportion-Air products are especially suited to medical applications. Our units are used across medical device manufacturing, from controlling the pressure to make medical tubing to testing the performance of sensitive equipment, as well as a vital component in medical equipment for procedures like phacoemulsification cataract surgery.

How They Work

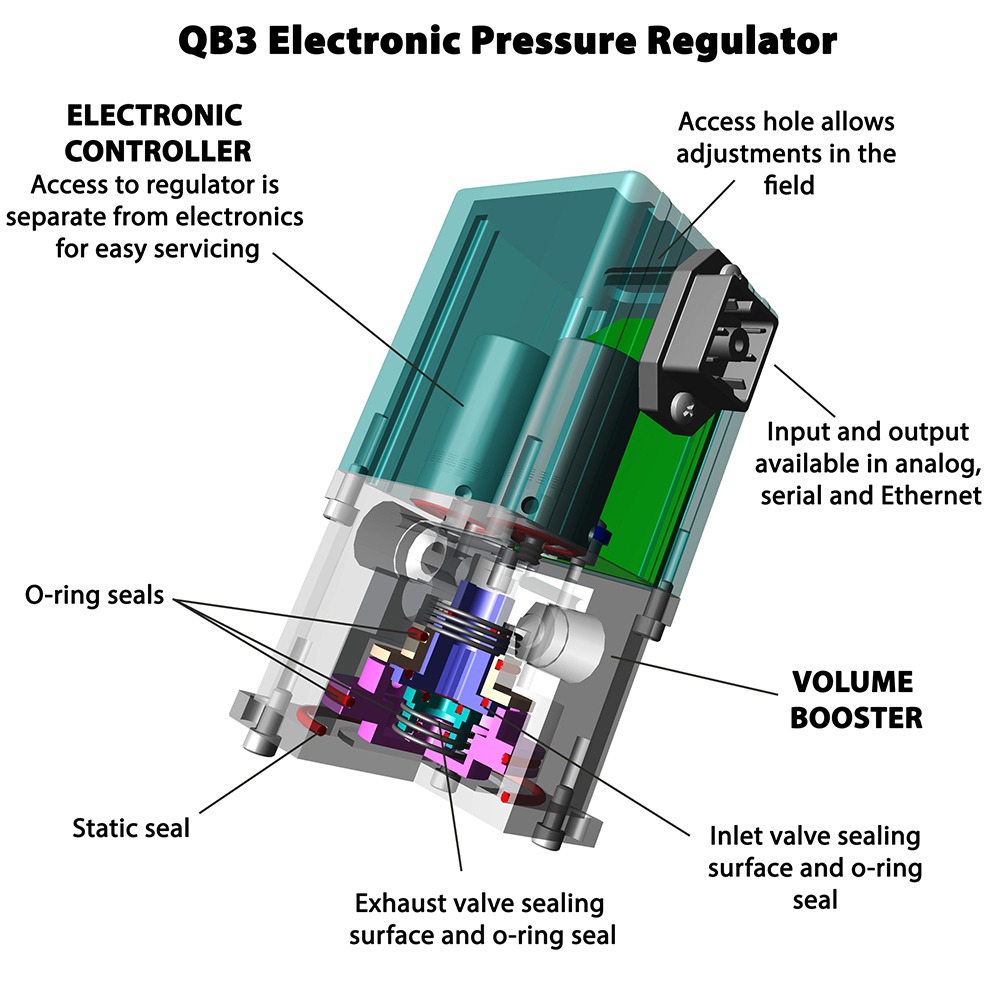

All of our electronic pressure regulators are closed loop, featuring an internal sensor that provides feedback. Dual loop options, which receive feedback from a downstream sensor, are available as well. Nearly all of our regulators offer vacuum control. Vacuum-through-positive control is also available, which eliminates the need for two separate devices. Our devices are compatible with many pneumatic media. Options include compressed air, nitrogen, helium and other inert gases.

Leak Testing for Medical Devices and Processes

Many medical products undergo rigorous testing to protect both patients and device operators. Our valves can be used to execute reliable and repeatable leak testing methods that can be configured exactly for your needs for medical products like inflatable cuffs, IV fluid bags or catheters.

High Pressure Pneumatic Control

High pressures are often required for processes like balloon angioplasty catheter blow molding, extrusion and burst testing. High pressure leak testing is another common application we can handle to ensure your product meets quality control standards.

Medical Product Coating

Consistent, repeatable processes for coating catheters, stents and other biomedical products with polymers or drug coating is a necessity. Well-applied coatings protect the device from corrosion, protect against complications such as tissue trauma or infection, or are used as a method to deliver a slow release medication. Using an electro-pneumatic regulator for pressure control ensures uniform results, which helps prevent irregular coatings and limits downtime.

Medical Tube and Hose Manufacturing

Medical tube extrusion requires that exact wall thickness and diameter is correctly maintained throughout the extrusion process. Our customers produce medical tubes and hoses for everything from tourniquets to ventilators and respiratory equipment.

Microfluidic Pressure and Flow Control

Low-flow microfluidic applications – those controlling very small amounts of fluids – are becoming one of our specialties. Whether controlling single or multiple channels, our high resolution (up to ±0.005% of full scale calibration), high accuracy valves provide reliable and repeatable pressure control, resulting in stable and reproducible conditions and precision flow control through the channels.

Knowledgeable Customer Support

Contact our team using the information on this page to work with one of our knowledgeable application specialists about your project and goals. We’re happy to help you design one of our devices to meet your specific needs.