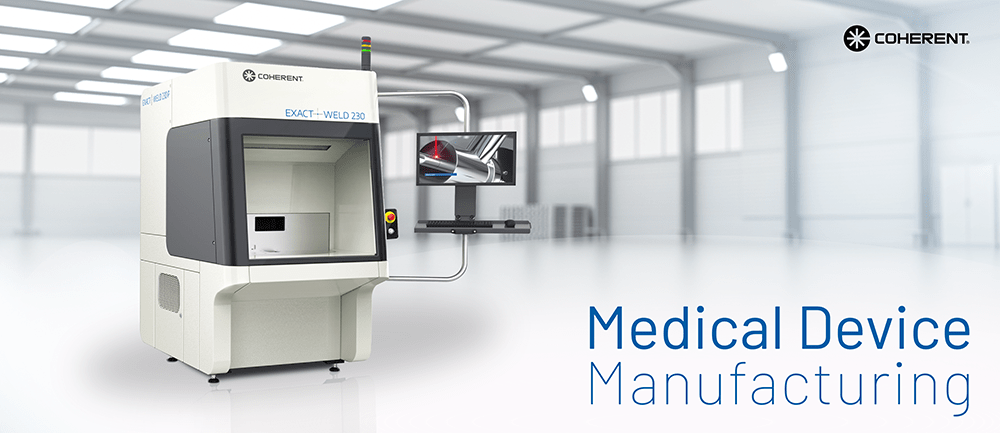

The ExactWeld 230 enables cost-effective high-precision laser welding of small to medium sized metal parts. It is ideally suited for medical device manufacturing, including endoscope production, fabrication of precision sensors, jewelry, watches and automotive electronics.

Turnkey Solution for High-Precision Welding

The system is powered by our latest fiber laser technology and provides low cost of ownership through high productivity and enhanced ease-of-use. It comprises a up to 400 W fiber laser, robotic part clamping and four axes (x, y, z, θ) positioning, user-friendly software, and an optional integrated vision system. In addition it offers factory automation capabilities to enhance the quality, production yields and throughput of metal part welding at maximum process consistency and operator productivity.

ExactWeld 230 also incorporates the unique Coherent patented SmartWeld™ technology for producing complex “beam wobble” patterns, including even circular and zigzag paths. SmartWeld™ enables bridging of larger gap widths which relaxes fit-up tolerances, increases process flexibility, and delivers welds with higher quality and reproducibility.

Intuitive Operation

The system features simplified operation. Control is via an easy-to-use GUI with a 24” touch screen monitor, together with a user-friendly software suite that integrates all the laser and motion functions of the system. A library of intuitive routines streamlines the task of creating the complete recipe for each welding application.

Features & Benefits

- High-productivity precision welding system with patented

SmartWeld™ technology - Powered by latest fiber laser technology

- Class 1 laser housing meets the newest ergonomic guidelines

- Welded steel construction base frame

- High process consistency

- Industry 4.0 ready

- Servo motor with X/Y/Z axis travel

- Large working chamber

- Pneumatic lifting door and rotary table available

More information on our website: https://www.coherent.com/lasers/laser/exactweld-230