Gauges are essentially the sole interface between the measured object and the measured value and it is safe to say that this value lies at the beginning of all quality management efforts. If, for whatever reason, the value is not measured correctly, all subsequent QM processes such as incoming/outgoing goods inspections will be in vain.

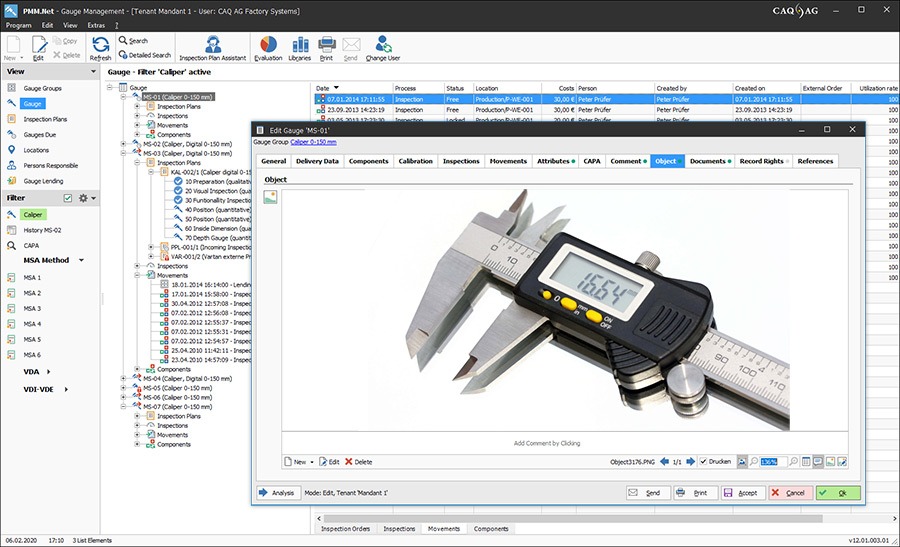

The software application PMM.Net supports you throughout the planning, administration, control, calibration, and capability analysis of your gauges. It effortlessly facilitates highly effective and efficient gauge management – from simple calipers to the most complex multi-dimensional gauges.

The application of the PMM.Net software solution allows you to perform gauge management as an active process. It facilitates the planning and monitoring of both freely determined and manufacturer-specific maintenance intervals. For example, maintenance intervals can be planned dynamically according to wear and tear or freely according to individual time intervals.

All processes are subsequently monitored and documented automatically. Throughout all of this it doesn’t matter whether you wish to monitor 10, 1000 or 100,000 gauges: all relevant information such as type of device, ID-number, location, specification, current user, calibration interval, or calibration results is consistently maintained in the system for each individual gauge.

True to the idea of efficiency, PMM.Net also provides comprehensive assistance for cost and finance management matters as well. It allows you to conveniently retrieve current sums and facts regarding maintenance, inspections, or calibrations at the click of a button and use this data to compile detailed cost-centre or gauge-specific financial overviews. The software application thereby allows you to lay the foundations for effective and efficient gauge-related cost controlling.

More information on our website: https://www.caq.de/en/Software/Gauge-Management