Under the deal, Lubrizol Deutschland, a German subsidiary of Lubrizol, has purchased the stake in Bavaria Medizin Technologie from its current majority shareholder Custos Vermögensverwaltungs and minority shareholders

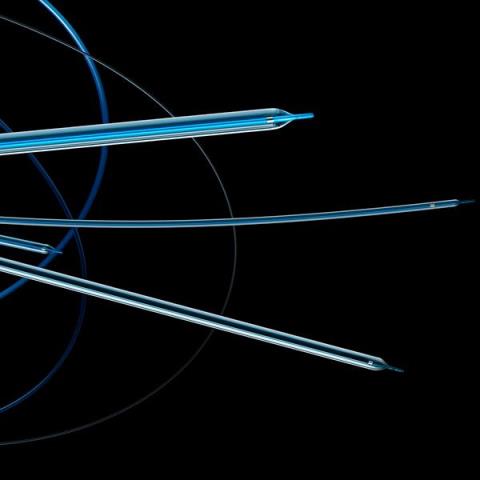

Based in Munich, Bavaria Medizin is specialised in designing and manufacturing different types of catheters and delivery devices for intravascular and nonvascular devices.

The company produces a variety of medical devices such as catheters for coronary, peripheral and cranial indications. It also manufactures dilatation catheters, devices for local drug delivery, stent delivery devices, as well as ENT devices and several other devices.

Paccocath catheter is the firm’s first commercial drug-coated balloon, and it currently holds more than 50 patents for its products.

Bavaria Medizin is also engaged in the private label manufacturing of catheters and balloons. It also offers original equipment manufacturing (OEM) services, including the manufacturing of subassemblies and components, sterilisation, packaging and labelling, stent crimping, and logistics management.

With more than 100 employees, Bavaria Medizin has a manufacturing facility in Sibiu of Romania.

The acquisition of Bavaria Medizin is believed to help Lubrizol to enhance its product design, development, and manufacturing expertise, in addition to accessing proprietary catheter and balloon technologies.

Bavaria Medizin’s experience in the drug-coated balloon (DCB) space is said to align with Lubrizol’s pharmaceutical CDMO business and help in the development of next-generation DCBs.

Lubrizol Life Science’ health business general manager Uwe Winzen said: “Lubrizol continues to invest in opportunities that position us as a full-service development partner for innovative OEMs in the interventional space.

“Our customers will benefit from additional design capabilities, an increased global footprint, and synergies with our existing formulation and manufacturing services.”

The acquisition is expected to complement Lubrizol’s expertise in precision thermoplastic extrusion and product development, helping to establish the company as an end-to-end partner for the global medical device and pharmaceutical industries.