3D Systems has announced its new Print to Perfusion process – a breakthrough technology that enables the rapid bioprinting of human solid-organ scaffolds.

The American additive manufacturing firm claims its work alongside biotech company United Therapeutics has led to “tremendous progress” in printing full-size, vascularised lung scaffolds at high speeds.

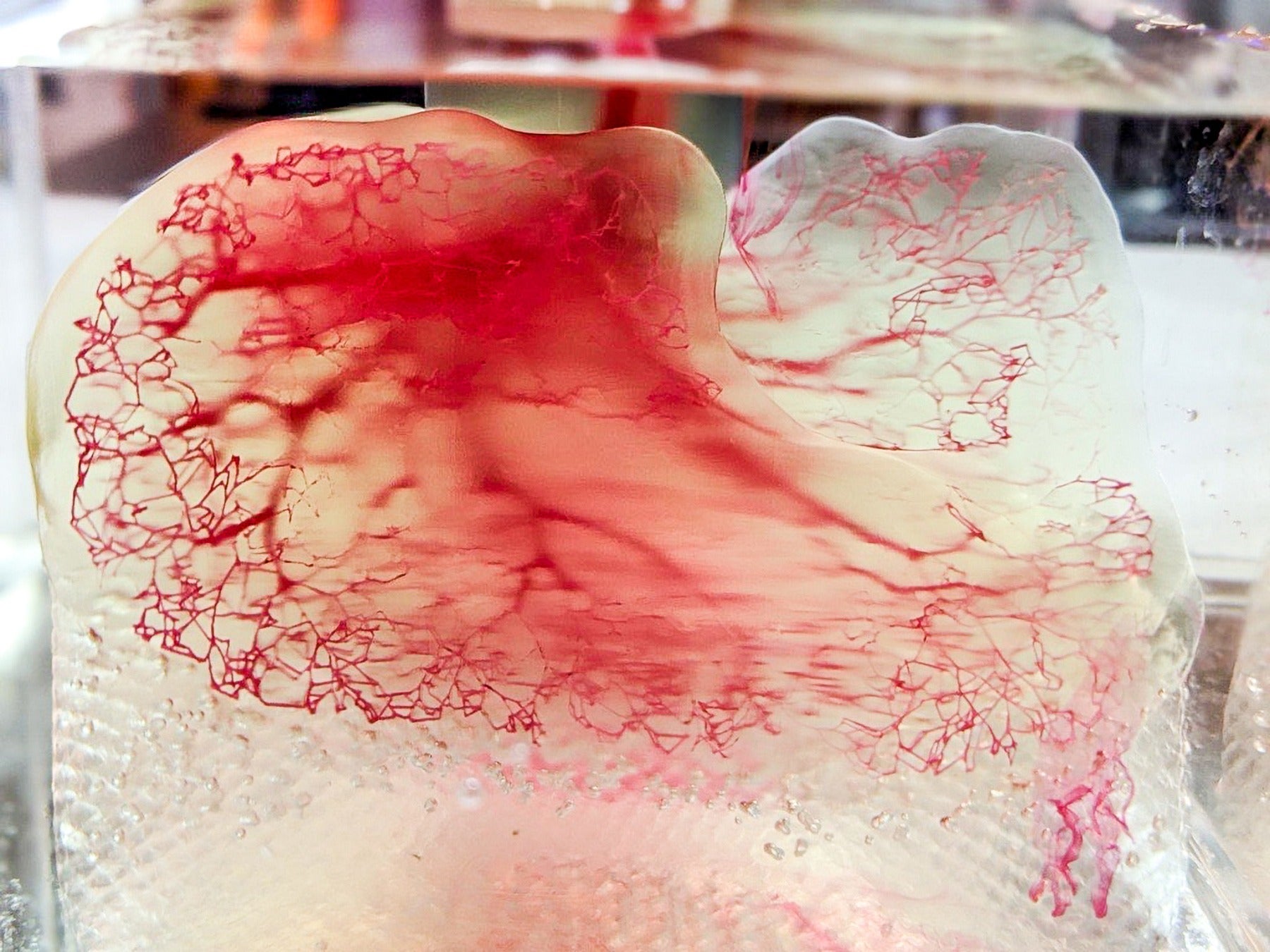

These scaffolds can then be perfused with living human cells to create tissues, potentially allowing the two companies to build an unlimited supply of transplantable organs.

In the future, this could enable novel laboratory testing methods to accelerate the development of new drug therapies while simultaneously reducing the need for animal testing.

In light of this breakthrough, 3D Systems is also expanding its work in the field of regenerative medicine even further, and the South Carolina-based firm claimed it will now explore other areas within the human body – including the development of non-solid organ applications requiring biologically sustainable vasculature.

Chuck Hull, co-founder, executive vice president and chief technology officer, 3D Systems, said: “Over the last years, as bioprinting and regenerative medicine have evolved, we’ve seen a growing need to place cells at high-resolution in a nurturing matrix to produce complex tissues.

“Precise 3D printing with hydrogels, followed by perfusion of cells into the printed scaffold, is the best way to achieve this – and we are thankful our work with United Therapeutics has given us the opportunity to advance and perfect this technology.”

3D Systems’ new bioprinting technology

In 2020, 3D Systems and United Therapeutics – via its organ manufacturing and transplantation-focused subsidiary, Lung Biotechnology PBC – achieved “significant progress” in the development of a next-generation additive manufacturing platform for lung scaffolds that is capable of full-size, vascularised, rapid, micron-level printing.

3D Systems claims its capabilities as a technology innovator and 3D printing provider for the healthcare industry, alongside United Therapeutics’ expertise in regenerative medicine, made these advances in lung modelling and 3D bioprinting possible.

Through the development of Print to Perfusion, these capabilities have also enabled progress in material formulation using a unique rhCollagen – CollPlant’s recombinant human collagen BioInk technology – and material handling to yield new possibilities in bioprinters and biomaterials for lung manufacturing.

Derek Morris, associate director of engineering, Lung Biotechnology PBC, said: “Our collaboration with 3D Systems has allowed us to take a first-principles approach to regenerative medicine.

“The full-size, vascularised lung scaffolds produced by 3D Systems’ printers allow our cellularisation teams to focus on our mission to build an unlimited supply of transplantable organs.”

3D Systems’ newly-developed Print to Perfusion process allows 3D printing of high-resolution scaffolds that can be perfused with living cells to create tissues.

The ability to rapidly print large, vascularised, highly detailed hydrogel scaffolds is now opening new opportunities for a range of tissue applications, according to the US firm.

To advance these efforts further, 3D Systems is expanding its high-speed Figure 4 technology through innovation tailored to bioprinting and regenerative medicine, and hopes to build upon these capabilities to progress numerous applications within the human body via collaboration with its partners.